Current state: in service

A pillar of our association is the steam locomotive Tubize 2069 "Helena", within the association she is called Tubize. Today she is the strongest steam locomotive in running order in the workshop in Baasrode. Meanwhile, she has been through a lot: from first rolling out of the factory, to a period without a certain future, to finally being allowed to participate in Europe's most important steam train festival. So, to tell the whole story, we will start with the context behind her origins.

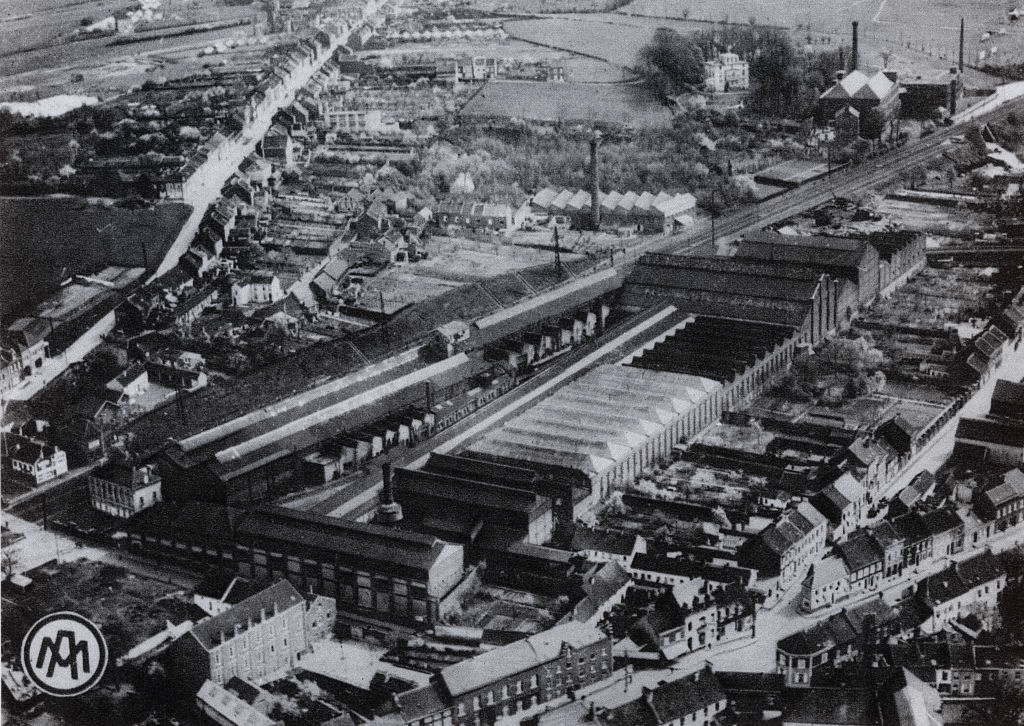

In 1854, the "Société Anonyme la Métallurgique" was created when a locomotive workshop was set up in the municipality of Tubize, Tubize in French. Over the years, the workshop grew into a huge locomotive manufacturer. Domestically, they produced a huge variety of locomotives, some for private sector factories, but also some built on behalf of the Belgian state railways. The firm also achieved great success internationally, locomotives from Tubize reaching as far afield as Finland, Greece and Taiwan. The Société Anonyme would also change its name to "Ateliers métallurgiques" and the workshop in Tubize became one of many and changed its name to "Ateliers de Tubize".

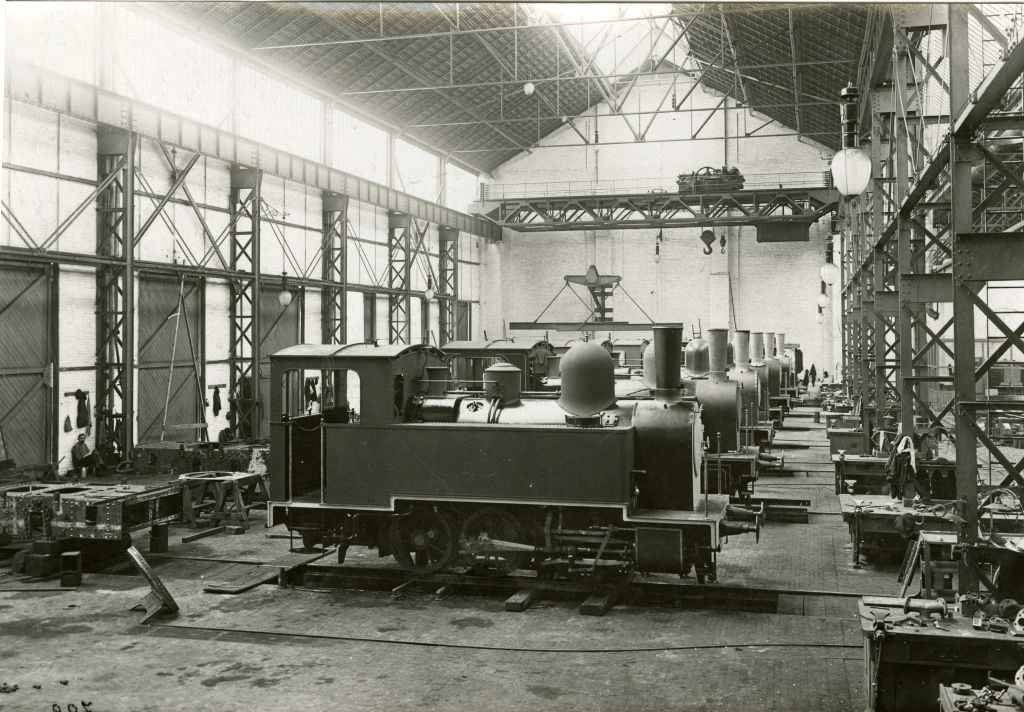

It so happened that a company, based in Hoboken, would make an order with the Ateliers de Tubize for 3 steam locomotives. The company, then known as Métallurgie Hoboken, needed these to move goods from one factory hall to another on their large site. The locomotives had 3 coupled axles to provide enough power. In 1927, 2069 "Helena" rolled out of the factory along with locomotive 2068 and 2070. From then on, they began an almost 50-year career at Métallurgie Hoboken.

Cast aside in the 1970s, her two sister locomotives met a more complex end. They were to be experimentally converted to diesel locomotives; not much of the original locomotives remained. Helena, precisely because she was not converted, was kept as a strategic reserve for the plant and was thus also set aside in working condition. In 1988, the locomotive came to the collector Sobemai, a crane company in Maldegem, besides which the owner was a fan of railways. Besides Tubize, she also kept Cockerill 2643 from SDP, Cockerill 503 from at Train 1900 and Energie 507 also from at Train 1900. She spent only a few months at Sobemai. As a result of the foundation of not only the Belgian Friends of the Steam Train (Old name of Stoomtrein Dendermonde Puurs) but also their re-opening of railway line 52M (Dendermonde-Puurs) Tubize came to Baasrode North station, this would have been a donation)

The year 1991 arrived, Tubize had been in Baasrode for 2 full years, however there were no plans to restore her then. The facilities in Baasrode at the time were not optimal to restore a steam locomotive so it was opted to bring over a working steam locomotive from Germany at a much higher price. That locomotive became Duvel and was financed partly from subsidies, partly from partnership with brewery Duvel Moortgat and partly from the sale of Tubize. It was thus sold in 1991 to a new non-profit association, which was named VZW Tubize 2069 when it was founded. VZW Tubize 2069 made the purchase possible without Tubize having to move away from Baasrode. The locomotive Duvel would run at BVS from 1993 to 1997, after which it was permanently sidelined. After 4 years with Duvel running, it was back to Cockerill 2643 to run train traffic between Puurs and Dendermonde. For a few years things were like this again, in the meantime metallurgy became Hoboken, Umicore. Behind the scenes, things were finally happening again for Tubize.

In 2001, Tubize began her major restoration. From head to toe she was sanded down, repainted, tubes were put on new or replaced until finally in 2007 she could drive out of the shed at Baasrode North Station under her own power. From the start it was a success story at BVS/SDP, she was able to take over the trains from the locomotive Cockerill because in comparison Tubize is much bigger and stronger. She also went to visit CFB (Chemin de Fer du Bocq) several times for their annual festival and also visited Maldegem Eeklo Steam Train (then Steam Centre Maldegem).

However, in 2014, she had to be taken out of service due to boiler problems. Then VZW Tubize 2069 ran into a dilemma, a new boiler would be expensive and a repair would be extremely labour-intensive. One preferred option 2, so it happened that week after week, every Saturday the volunteers crawled into the boiler to replace rivets or remove the thin pieces. One of the last boiler welders, a profession that no longer exists in Belgium, came to help weld the new pieces of steel into the boiler.

After six years in restoration, in 2020, Tubize could drive again. Unfortunately, this was plenty during the Covid-19 pandemic so it was opted to continue tinkering for another year. Now she pulls most of the trains at SDP, after all the years of service she still proves to be a versatile machine. Apart from taking part in Scheldeland in Steam every year, she has since been to the Chemin de fer du Bocq and the Chemin de fer à vapeur de trois Vallées several times. She has also been abroad twice, once visiting Train 1900's Fond-de-Gras in 2022. She also visited the Parawozownia Wolzstyn in 2023 for their annual festival. Located in Poland, Wolsztyn is known for their spectacular festival where they annually bring together some of Europe's most impressive locomotives. Tubize travelled as much as 1,000 kilometres to visit the railway. She rode not only at the festival but also the whole week after. In Poland, she got to drive distances and speeds she could never have driven in Belgium.

| Mass | 42,4 T |

| Year of construction | 1927 |

| Maximum speed | 40-50km/h |

| Power | 400 HP |

| Factory no. | 2069 |

| Stock | 1700 kg coal 4500 l water |

| Axle layout | C |

| Diameter of wheels | 1100mm |

| Builder | Ateliers Métallurgiques de Tubize |

| Operating principle | Horizontal boiler with flame tubes |

| Max. operating pressure | 12 bar |

| Flame tubes | steel 198 units |

| Fire box | Copper |

| Boiler | Steel Wall thickness: 15 mm Total heated area: 104m² Volume: 5.45m³ Steam percentage: 15% |

| Water filling system | 2 injectors Type Gresham (self-priming) |

| Cylinders | 2 units Diameter: 430mm Stroke length: 550mm |

| Steam distribution & control | Sliding Walschaerts scheme |

Photo gallery